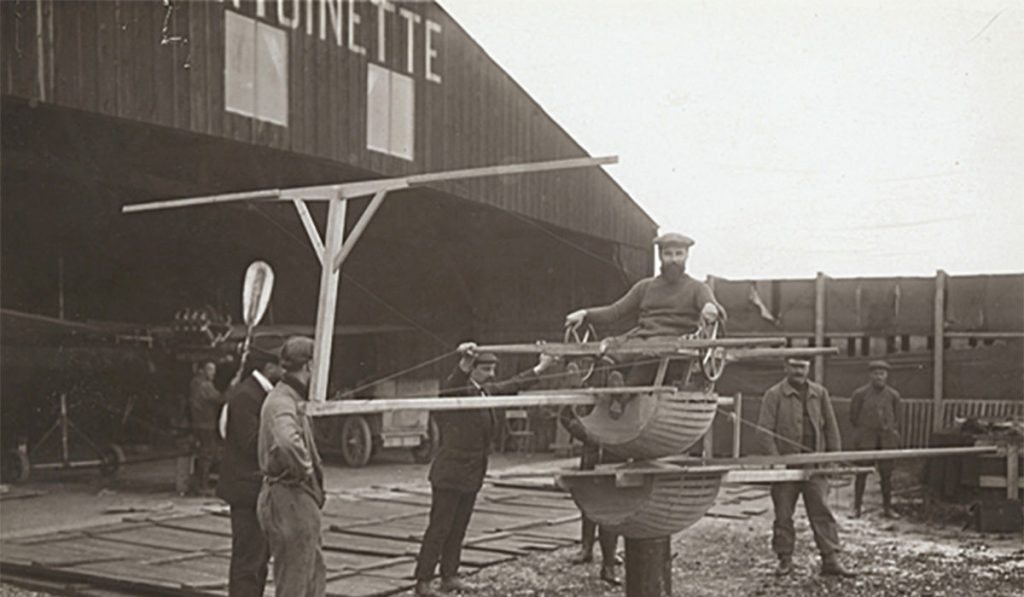

Most people, if you ask them to describe simulation in an aviation context, will respond with a description of a flight simulator. And that is a perfectly understandable and reasonable response. After all, flight simulators have been around since the very beginning of heavier than air flight. As early as 1910, an article in Flight magazine extolled the virtues of a device called the Sanders Teacher, which consisted of a modified aircraft mounted to a universal joint that was fixed to the ground. Also in 1910, the Wright Brothers designed a flight simulator based on repurposing a Wright Flyer. At the same time in France, the Antoinette company developed a flight simulator to accompany a new aircraft that was designed to meet a commission from the French military – a principle that is followed for all modern military and commercial aircraft.

The technology in flight simulators has evolved alongside that of the aircraft themselves, with modern flight simulators for both military and commercial aircraft providing immersive, high fidelity representations of the aircraft flight and handling characteristics, avionics and other systems. In the case of military, simulations include weapons and sensors, as well as representations of hostile, friendly and neutral forces. Not only do these military simulators enable individual pilots to be trained, but they can be networked with other simulators, or real-world platforms, to enable joint collective training to be carried out. In both military and commercial aviation, simulators are an essential component in ensuring safety and mission readiness for pilots and mission aircrew.

But simulation, and modelling, is a more fundamental capability enabler and force multiplier for defence than just individual and collective training. In today’s increasing complex world, simulation is an essential element of the entire capability life cycle. Simulation is regularly applied in force design, exploration of capability options, experimentation in developing new techniques, tactics and procedures. (Note model a model can be defined as a mathematical abstraction of a physical phenomenon, a system or a process, and a simulation as an iteration of a model over time).

Modelling and Simulation (M&S) is explicitly stated as being a key enabler of US Department of Defense activities. To quote from the US DoD Modeling and Simulation Enterprise (MSE) website (US Department of Defense, 2020):

“Modeling and simulation is a key enabler of Department of Defense (DoD) capabilities, supports the full range and scope of DoD missions and operations, underpins innovative solutions meeting national security challenges, and saves resources. Over the past 20-plus years, M&S has become pervasive, almost ubiquitous, throughout the Department.”

Modelling and Simulation is equally seen as important in Europe. For example, the NATO M&S Centre of Excellence was established to promote the use of M&S in support of operational requirements, training and interoperability. The Centre acts as a catalyst for transformation through the involvement of NATO, governments, academia, industry, operational and training entities.

To further illustrate the thinking in the US, a recent address at the US Air Force Association’s 2020 Virtual Air, Space and Cyber conference by Dr. Will Roper, Assistant Secretary of the Air Force for Acquisition, Technology and Logistics highlighted the challenges faced by the USAF in the face of the ever-accelerating pace of technology. Dr Roper said “If you look at the world in which we live today, we must be agile. There are too many possible futures for us to pick one and build a force that’s geared to defeat it.” In the same address he went on to say “With the use of digital engineering, the Air and Space Forces can build unique systems in an environment where unique technology is always being redesigned, optimized and tested digitally, as opposed to using blueprints or computer models “that were good approximations for the physical system, but not the same as the real thing.” The USAF even has a new weapons system series designator for this – the ‘e’ series. The first system to receive this designator is the Boeing eT7-A Red Hawk advanced trainer.

Modelling and simulation are fundamental to this Digital Engineering paradigm, which in other circles is referred to as the use of Digital Twins. The approach can also be seen as extending the Model Based Systems Engineering paradigm, an approach which has been referred to as Modelling and Simulation Based Systems Engineering. To be effective across the full capability lifecycle, the scope of a digital engineering solution must include a model of the environment in which a system operates, including interfacing systems. These interfacing systems could also be enabling systems, that is, those systems needed to support the development, management or sustainment of the system.

In order to make optimal use of these Digital Engineering models, interoperability between models will become more and more important. This will be essential in order to build operational models and simulations of joint and coalition capabilities, and to enable data sharing and re-use of models and simulations.

Additionally, use of modelling and simulation based Digital Engineering is essential in the successful deployment of Artificial Intelligence based systems, including Robotic Autonomous Systems. Such systems, which themselves contains models, can only be properly developed, trained and evaluated within simulation-based environments. And this needs to happen continually, as AI systems are able to learn and adapt their behaviours.

The importance of modelling and simulation is also recognised by the Australian Defence Force (ADF). For example, the foreword of the recently released Sovereign Industrial Capability Priority Implementation Plan for Test, Evaluation, Certification, and Systems Assurance notes that “the rapid change in technology associated with these capabilities results in a need for more agile testing methodologies, including using models and simulations within live, virtual and constructive environments”. Increased use of modelling and simulation is seen as an important approach in enabling the ADF and industry to address future trends and technological evolutions, and the document also recommends:

- “Using broader industry and commercial sector developments in using Live, Virtual, and Constructive modelling and simulation to support and improve testing and certification outcomes.

- Expanding the use of synthetic representations that allow for virtual product and production design through to real-world automated production, operating models and reduced risks of achieving performance.

- Leveraging the Defence virtual training environment to include modern Defence and industry test and evaluation facilities, training areas and ranges that are integrated, networked, and incorporate routine use of Live, Virtual, and Constructive modelling and simulation. “

Given the central role that modelling and simulation already plays, and the fact that this role will only grow in significance, it is essential that modelling and simulation skills are acknowledged as critical to Australia’s security. Not only that, in my view it is time that Modelling and Simulation is recognised as a Strategic Industry Capability Priority (SICP) in its own right. To quote from the 2016 Defence Industry Policy Statement:

“There are some capabilities that are so important to Australian Defence missions that they must be developed or supported by Australian industry because overseas sources do not provide the required security or assurances we need. As such, it is critical that the industry base associated with these capabilities is maintained and supported by Defence as sovereign industrial capabilities.“

Modelling and Simulation well and truly meets this criterion. Restating some earlier points with a sovereign capability perspective as examples:

- M&S enables objective assessment of future capability options. A country has to have sovereign control over this activity.

- M&S is a key element of the Digital Engineering approach to systems development and sustainment. The ability to evolve and adapt local solutions to local needs will depend more and more on access of a sovereign M&S capability.

- The functionality in simulation trainers determines what knowledge transfer may be achieved in training, as well as enabling the development of new techniques, tactics and procedures. Australia must have control over how the skillsets and knowledge needing to be developed in ADF personnel are implemented in simulations. Only sovereign control over development of simulation training systems enables this.

- M&S enables mission planning and rehearsal. A country has to be able to do that secure in knowledge that no other country knows what it may be planning. The enabling technology (M&S) must therefore be sovereign controlled

Australian industry already has a significant modelling and simulation capability – including appropriately targeted modelling and simulation related SICP requirements in defence procurement programs would not onerous. For example, Cirrus Real Time Processing Systems (“Cirrus”) is an Australian SME successfully developing M&S technology for the ADF, with multiple simulation systems supporting training in sophisticated military mission systems. All Cirrus simulation systems are based on Australian technology and IP developed in-country by Cirrus’ engineering team, and represent sovereign industrial capability in support of the ADF. At the other end of the spectrum, large international organisations such as Thales, Raytheon, Boeing, CAE and others have significant local M&S capabilities, and have made large investments in M&S research and development in Australia.

To complement the industry capability, there is a very strong modelling and simulation research capability in Australia’s universities, and there are many collaborations underway between industry and academia in the M&S space. The modelling and simulation sector is also supported by a professional association, Simulation Australasia. One of the key missions for Simulation Australasia is to encourage these links, and to enable the sharing information across different industry sectors.

Crucial to the effective application of M&S in Australia will be increased strategic knowledge of M&S by government policy makers and industry leaders. The US could provide another example here, where the Congressional Modeling & Simulation Caucus has been active since 2005. The M&S Caucus includes four members of Congress and meets regularly with industry leaders to advocate for the use of M&S in analysis, design, testing, and training.

Australian modelling and simulation companies and universities are ready to stand up and meet the challenge – it’s time for modelling and simulation to come out of the shadows and receive the recognition it deserves!

Main pic Wedgetail Operational Flight Simulator. Boeing image.